Preventive maintenance is a crucial aspect of ensuring the longevity and efficiency of equipment, machinery, and infrastructure. By implementing a preventive maintenance checklist, businesses can proactively address issues before they escalate into costly repairs or downtime. This checklist serves as a guide for regularly inspecting, testing, and servicing equipment to prevent breakdowns and extend its lifespan.

What is a Preventive Maintenance Checklist?

A preventive maintenance checklist is a comprehensive list of tasks that need to be performed on a regular basis to keep equipment in optimal condition. It typically includes items such as lubrication, inspection of components, calibration of instruments, and replacement of worn parts. By following a preventive maintenance checklist, businesses can reduce the risk of unexpected breakdowns and extend the life of their equipment.

The Purpose of a Preventive Maintenance Checklist

Image Source: propertymeld.com

The primary purpose of a preventive maintenance checklist is to prevent equipment failure and downtime. By regularly inspecting and servicing equipment, businesses can identify potential issues early on and address them before they become major problems. This proactive approach helps minimize the risk of costly repairs, prolongs the lifespan of equipment, and ensures optimal performance.

Why Implement a Preventive Maintenance Checklist?

Implementing a preventive maintenance checklist offers several benefits for businesses, including:

Image Source: scribdassets.com

– Increased equipment reliability: Regular maintenance helps identify and address issues before they lead to breakdowns, improving the reliability of equipment.

– Cost savings: Preventive maintenance can help businesses avoid costly repairs and downtime, saving them money in the long run.

– Extended equipment lifespan: By properly maintaining equipment, businesses can extend its lifespan and maximize their investment.

– Improved safety: Regular inspections and maintenance help ensure that equipment is operating safely, reducing the risk of accidents or injuries.

How to Create a Preventive Maintenance Checklist

Creating a preventive maintenance checklist involves several steps:

Image Source: datocms-assets.com

1. Identify equipment: Make a list of all the equipment that needs to be included in the checklist.

2. Determine maintenance tasks: For each piece of equipment, identify the specific maintenance tasks that need to be performed, such as lubrication, inspection, or calibration.

3. Establish a schedule: Determine how often each task needs to be performed (daily, weekly, monthly, etc.).

4. Assign responsibilities: Clearly define who is responsible for performing each maintenance task.

5. Document procedures: Write detailed procedures for each maintenance task to ensure consistency and accuracy.

6. Implement a tracking system: Use a software program or spreadsheet to track maintenance tasks and ensure they are completed on time.

7. Review and update: Regularly review and update the preventive maintenance checklist to reflect any changes in equipment or procedures.

Tips for Successful Preventive Maintenance

To ensure the success of a preventive maintenance program, consider the following tips:

Image Source: googleusercontent.com

– Train staff: Provide training to staff members responsible for performing maintenance tasks to ensure they understand proper procedures.

– Use checklist templates: Utilize checklist templates to streamline the maintenance process and ensure consistency.

– Prioritize tasks: Identify critical maintenance tasks that are essential for equipment operation and prioritize them accordingly.

– Schedule downtime: Plan maintenance activities during scheduled downtime to minimize disruption to operations.

– Monitor performance: Track key performance indicators to assess the effectiveness of the preventive maintenance program and make improvements as needed.

– Seek feedback: Encourage feedback from staff members involved in maintenance activities to identify areas for improvement and address any issues proactively.

Implementing a preventive maintenance checklist is essential for businesses looking to ensure the reliability, safety, and efficiency of their equipment. By following a structured checklist and proactively addressing maintenance tasks, businesses can minimize the risk of unexpected breakdowns, reduce repair costs, and extend the lifespan of their equipment.

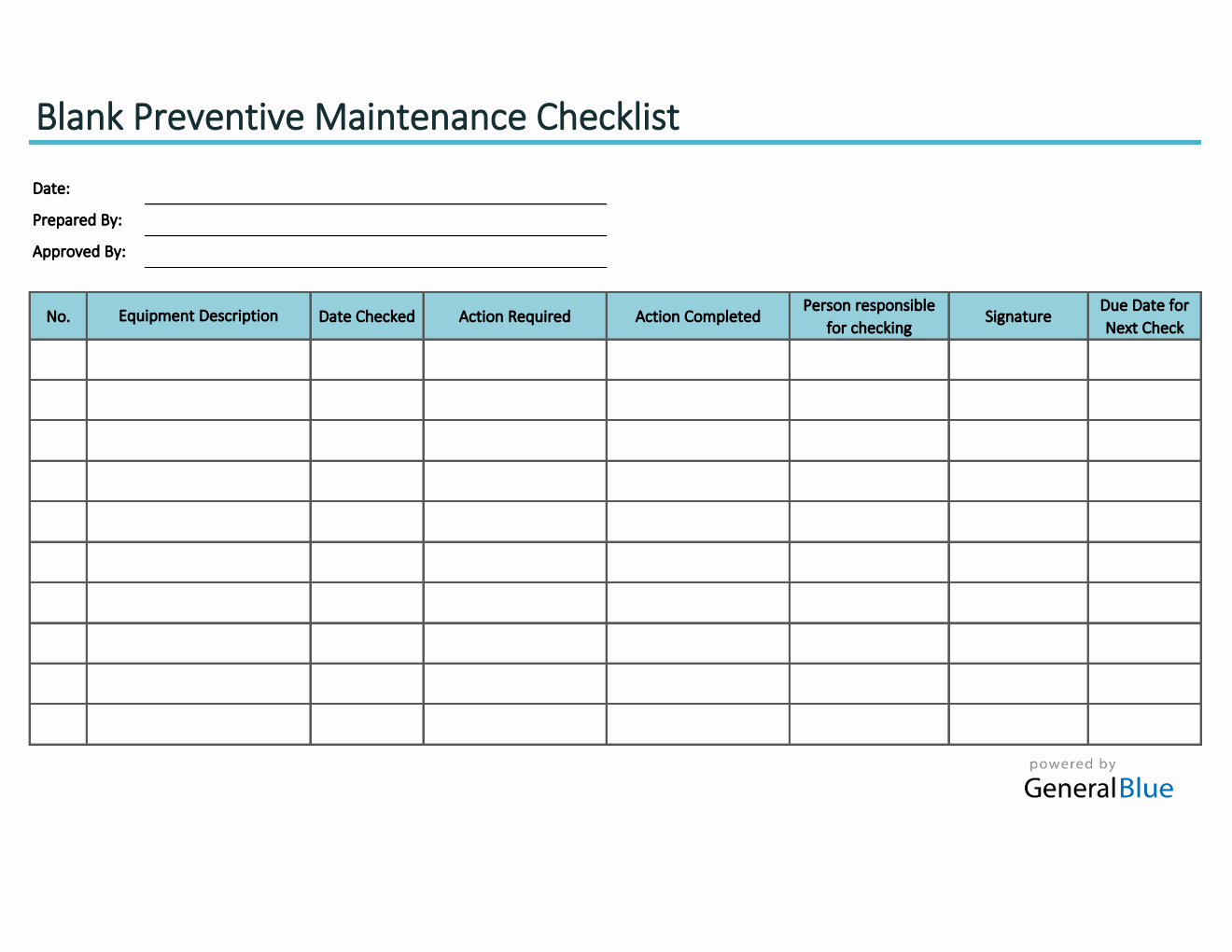

Image Source: generalblue.com

Image Source: sitemate.com

Image Source: firmresponse.com