In the fast-paced world of warehousing, effective inventory management is crucial for maintaining a smooth operation. One tool that can greatly assist in this process is a warehouse inventory list. This simple yet powerful document helps prevent overstocks and stockouts, provides valuable insights into product performance, and enables data-driven decision-making.

In this article, we will explore a warehouse inventory list, why it is important, how to create one, and provide tips for successful implementation.

What is a Warehouse Inventory List?

A warehouse inventory list is a comprehensive document that lists all the products and materials stored in a warehouse. It includes important details such as item names, quantities, locations, and other relevant information.

This list can be printed out and used as a physical reference or stored digitally for easy access.

Why is a Warehouse Inventory List Important?

A warehouse inventory list is important for several reasons:

- Preventing Overstocks and Stockouts: By having an accurate inventory list, warehouse managers can easily track the quantities of each item and ensure that they are not ordering too much or too little. This helps prevent overstocks, which tie up valuable warehouse space and cash flow, and stockouts, which can lead to dissatisfied customers and lost sales.

- Gaining Valuable Insights into Product Performance: With a comprehensive inventory list, warehouse managers can analyze data and identify patterns or trends in product performance. This information can help them make informed decisions about which products to reorder, which to promote, and which to discontinue.

- Enabling Data-Driven Decision-Making: A warehouse inventory list provides the foundation for data-driven decision-making. By having accurate and up-to-date inventory data, warehouse managers can make informed choices about inventory levels, reorder points, and other inventory management strategies.

How to Create a Warehouse Inventory List

Creating a warehouse inventory list is a straightforward process.

Here are the steps to follow:

- Gather all necessary information: Collect all the relevant details about each item in your warehouse, such as item name, SKU (stock keeping unit), quantity, location, and any other relevant information. This may require conducting a physical inventory count or using an inventory management system to gather the data.

- Choose a format: Decide whether you want to create a digital spreadsheet or a document. Both options have their advantages, so choose the format that works best for your warehouse and team.

- Create the list: Use a spreadsheet software or word processing software to create your inventory list. Organize the information in columns, with each row representing a different item. Include all the necessary details for each item.

- Review and update regularly: Inventory levels change frequently, so it is important to review and update your inventory list regularly. This will ensure that the information remains accurate and reliable.

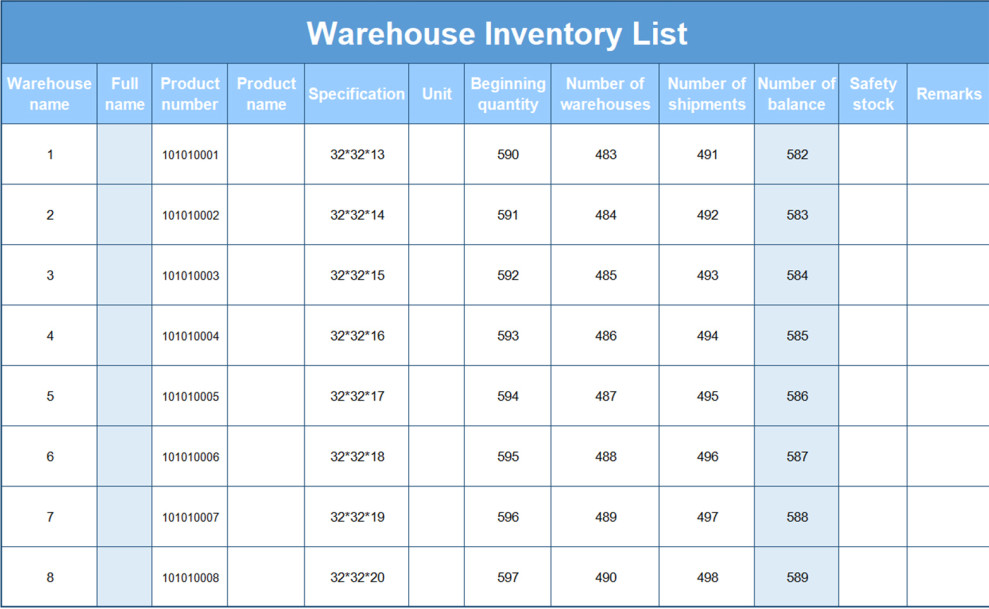

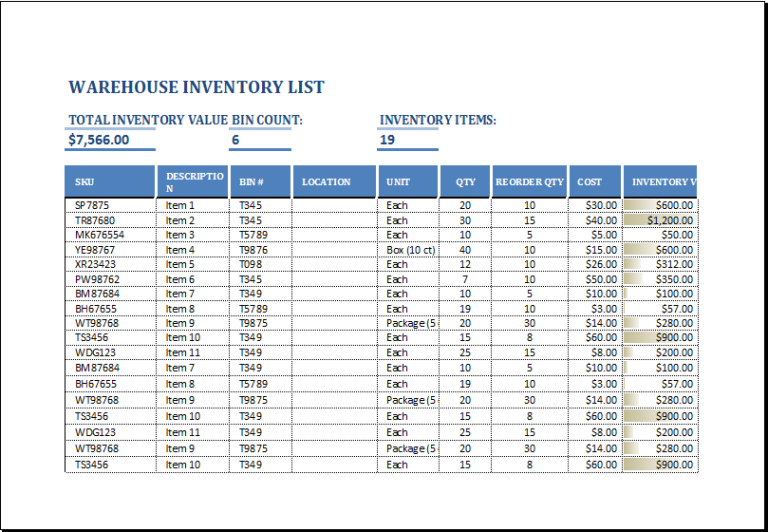

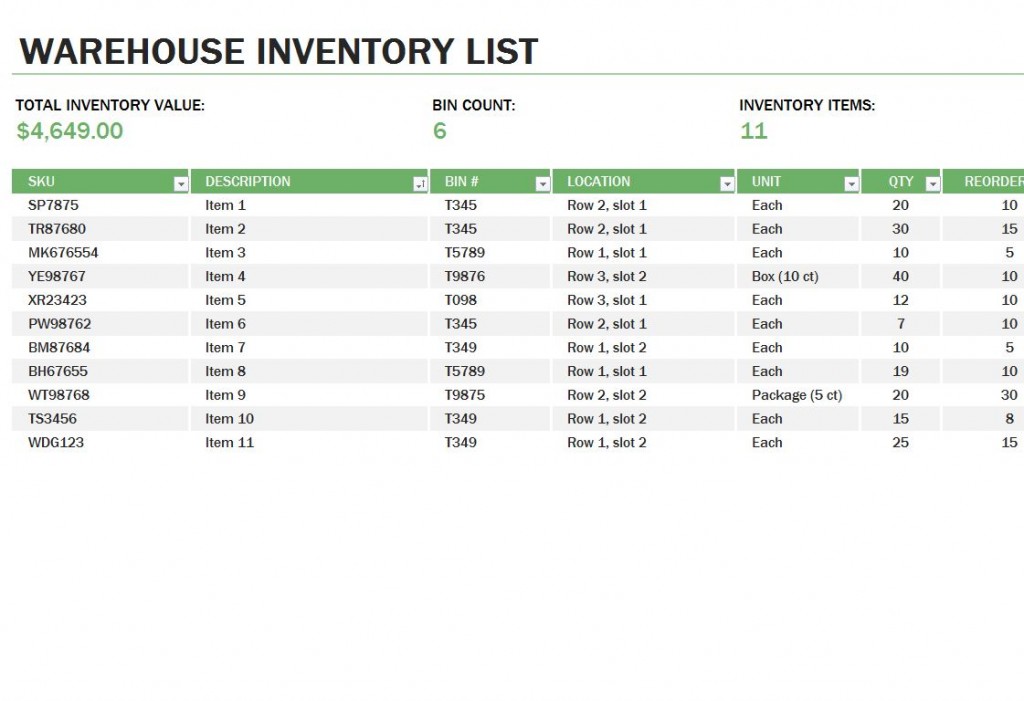

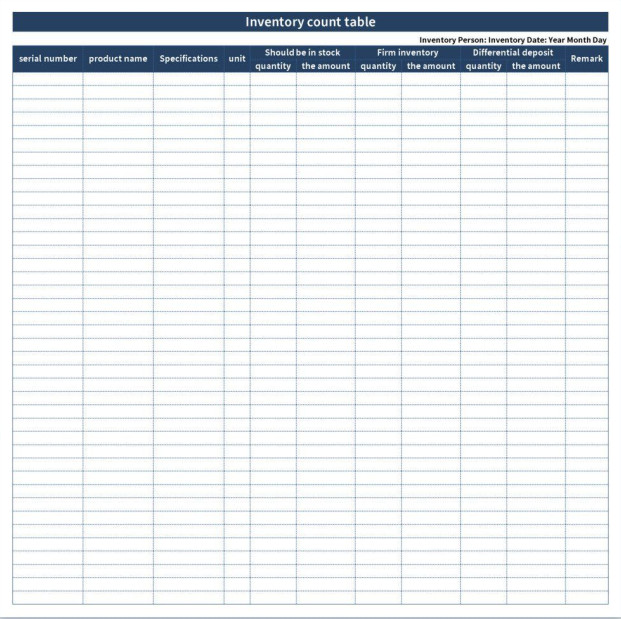

Examples

Here are some examples of what a warehouse inventory list might look like:

Tips for Successful Warehouse Inventory Management

Managing warehouse inventory effectively requires careful planning and execution. Here are some tips to help you succeed:

- Invest in inventory management software: Utilizing inventory management software can streamline your inventory management processes and provide real-time data for better decision-making.

- Implement barcode scanning: Barcode scanning can significantly improve the accuracy and efficiency of your inventory management. It eliminates manual data entry errors and allows for faster inventory counts.

- Regularly conduct physical inventory counts: While digital systems can provide real-time data, it is important to verify the accuracy of the information through regular physical inventory counts.

- Set up reorder points: Determine the minimum quantity at which you need to reorder each item. This will help prevent stockouts and ensure that you always have enough inventory on hand.

- Train your employees: Properly train your warehouse staff on inventory management procedures and ensure that they understand the importance of accurate data entry and record-keeping.

- Regularly analyze inventory data: Take the time to analyze your inventory data to identify trends, slow-moving items, and areas for improvement. This will help you make data-driven decisions and optimize your inventory levels.

- Collaborate with suppliers: Maintain open lines of communication with your suppliers to ensure timely deliveries and manage lead times effectively.

Conclusion

A warehouse inventory list is a valuable tool for preventing overstocks and stockouts, gaining insights into product performance, and making data-driven decisions. By creating and maintaining an accurate inventory list, warehouse managers can optimize their inventory levels, improve customer satisfaction, and increase profitability.

Follow the tips provided in this article to successfully implement a warehouse inventory management system and take control of your inventory.

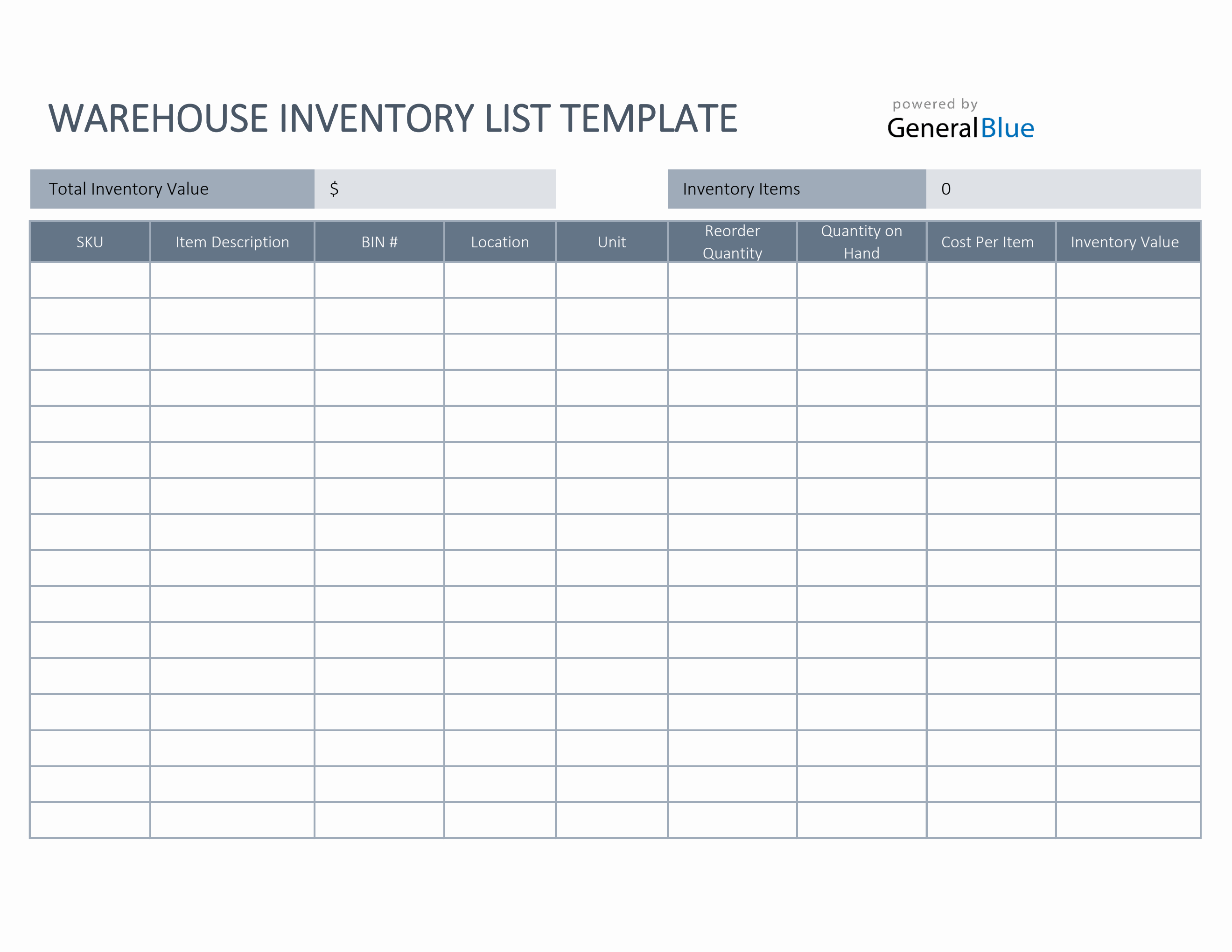

Warehouse Inventory List Template – Download